|

NINGBO RILSON SEALING MATERIAL CO.,LTD

|

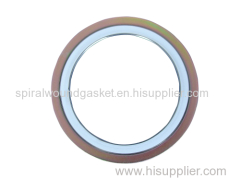

Graphite SS304 Spiral Wound Gasket

| Price: | 0.1~50.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1-Reduces inventory requirements

2-Easy to install... Less than half the studs

3-Multiple metal windings & fillers available

The spiral wound gasket depends upon the mechanical characteristics of a formed metal spiral strip, rather than the compressive virtues of more traditional gasket materials. This makes it particularly suitable for low or fluctuating bolt loads. The sealing strips, or fillers, are usually graphite, although other materials such as PTFE may be used, the windings are always s/steal. For this type or gasket to work the spiral must not be over compressed, hence one of two types of compression control used.

The completed gaskets is fitted into a steel ring of specific thickness. When the gasket is fitted into a flange and the bolt load is applied, flange closure is governed by the outer steel ring of the gasket. To further improve the pressure rating of the spiral wound gasket, s steel ring may be added to the inside. This also protects the windings (particularly the filler), from contamination, or attack by, the product.

Metal Winding Strip Materials | Filler Materials | Outer Ring Materials |

Gasket Selection

|  |  |

| Style CG - Utilizes an external ring which accurately centers gasket on flange face, provides additional radial strength to prevent gasket blow-out and acts as a compression stop. A general purpose gasket suitable for use with flat face and raised face flanges up to and inclusive of class 2500. See note at bottom of page 8 for inner ring requirements. | Style CGI - A Style CG gasket fitted with internal ring which gives an additional compression limiting stop and provides heat and corrosion barrier protecting gasket windings and preventing flange erosion. Suitable for use with flat face and raised face flanges. See note at bottom of page 8 for inner ring requirements. | Style R - Basic construction type. Inner and outer diameters are reinforced with several plies of metal without filler to give greater stability and better compression and sealing characteristics. Suitable for tongue and groove or male and female or grooved to flat face flange assemblies. |

Gasket Identification

Non Metallic Fillers The gasket filler materials are designated by a number of strips placed at equal intervals around the outside edge of the centering ring. |  |  |

Metallic Winding Materials The metallic winding material is designated by a solid color identification. |  |  |

Our Services

We work with our customers to make sure that they design and receive the most economical part, which meets their requirements and specifications.

We can manufacture from sample, technical drawing, or straight from electronic drawing file (such as a PDF and DOC files).

We also provide our customers with on-going technical advice and support.

Company Information

Company History

Rilson has been manufacturing custom gaskets and seals since 2007. Our gaskets have been used in well known buildings, famous works of art, and prototype space vehicles.

| Production Machinery: | ||||

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| Cutting Machine | No Information | 3 | 5 | Acceptable |

| Laser Cutting Machine | MESSER | 1 | 2 | Acceptable |

| Shearing Machine | Q11Y-6*25 | 1 | 6 | Acceptable |

| Punching Machine | JH21-125, JD23-25 | 6 | 3 | Acceptable |

| Instrument Machine Tools | SHENHUO & C0650 | 13 | 7 | Acceptable |

| Slot Milling Machine | No Information | 6 | 4 | Acceptable |

| Bending Machine | No Information | 7 | 1 | Acceptable |

| Winding Machine | FEIXIANG & PX500B | 11 | 5 | Acceptable |

| Automatic Winding Machine | No Information | 4 | 1 | Acceptable |

| Laser Printing Machine | TIANHONG | 2 | 2 | Acceptable |

| Testing Machinery: | ||||

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| Universal Testing Machine | GRANDTRY & WA-E | 1 | 3 | Acceptable |

| Certification: | |||||

| Certification Name | Certified By | Certificate No. | Product Name & Model No. | Available Date --- Expired Date | |

| ISO 9001:2008 | CQM, CNAS | CN-00212Q13397R0S | Scope: Production of Metal Winding Gasket, Metal Ring Gasket, Tooth From Gasket, Coating Gasket, Non-Graphite and Graphite Enhanced Gasket | 2012/06/29 --- 2015/06/28 | |

| Special Equipment Type Test Certificate | National Quality Supervision & Inspection Center of Sealing Product | TSX 71002520100040 | Flexible Graphite Spiral Wound Gasket (With Inside and Outside Ring) | 2010/03/31 --- 2049/12/31 | |

| Special Equipment Type Test Certificate | Special Equipment Type Test Certificate | TSX 71002520100039 | Flexible Graphite Spiral Wound Gasket (Ordinary Type) | 2010/03/31 --- 2049/12/31 | |

More interests please kindly send me an email or directly contact my Trademanager and I will reply as soon as possible.

.gif)