|

NINGBO RILSON SEALING MATERIAL CO.,LTD

|

ASME Non Asbestos Spiral Wound Gasket

| Price: | 0.1~50.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1-Reduces inventory requirements

2-Easy to install... Less than half the studs

3-Multiple metal windings & fillers available

The concept of spiral wound gasket construction was originated by Flexitallic in 1912, inaugurating the beginning of a new era in safe, effective sealing. And we are the main supplier of spiral wound gasket in China, also the main supplier of the Flexitallic Group Gaskets. The primary purpose for this development was the increasingly severe temperatures and pressures used by U.S. refinery operators in the first half of the century. The necessity for a gasket to have the ability to recover cannot be over emphasized. The effects of pressure and temperature fluctuations, the temperature differential across the flange face, together with bolt stress relaxation and creep, demand a gasket with adequate flexibility and recovery to maintain a seal even under these varying service conditions. The Rilson Spiral Wound Gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and pressure in flanged joints and similar assemblies and against virtually every known corrosive and toxic media.

Gasket Identification

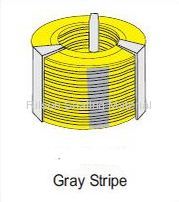

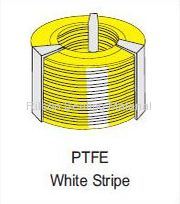

Non Metallic Fillers The gasket filler materials are designated by a number of strips placed at equal intervals around the outside edge of the centering ring. |  |  |

Metallic Winding Materials The metallic winding material is designated by a solid color identification. |  |  |

| Description | |

| Normal Pressure | 150# to 2500# |

| Normal Diameter | 1/2'' to 60'' |

| Usage | Flat and raised faced diameter flanges up to and inclusive of Class 2500. |

| Applicable Standards | ASME B16.20, BS, JIS, DIN, Suited for ASME B16.47 series A/B flanges |

| Hoop material | ss304, ss316L, 321, 317(L), Monel,Ti, Ni, INC, C/B Zr702, etc. |

| Filler | Graphite, PTFE, Non-asbestos, Mics, Monel, etc. |

| Inner & outer ring material | CS, ss304, ss316L, 321, 317(L), Monel,Ti, Ni, INC, Hast.C/B Zr702,etc. |

| Metallic strip | The standard thickness of the metallic strip is 0.2 mm. |

| Filler | Filler is normally used for thickness from 0.5 mm to 0.6 mm. |

| Centering ring | The centering ring does not come into direct contact with contained fluid. It is normally made of carbon steel and electro plated or painted to avoid corrosion. Other materials are available on request. |

| Inner ring | Inner ring is used to avoid excessive compression due to high seating stress in high-pressure service and it is also used to reduce turbulence in the flange area. It is normally made of the same material as the gasket metallic srtip. |

Gasket Selection

|  |  |

Style CG - Utilizes an external ring which accurately centers gasket on flange face, provides additional radial strength to prevent gasket blow-out and acts as a compression stop. A general purpose gasket suitable for use with flat face and raised face flanges up to and inclusive of class 2500. See note at bottom of page 8 for inner ring requirements. | Style CGI - A Style CG gasket fitted with internal ring which gives an additional compression limiting stop and provides heat and corrosion barrier protecting gasket windings and preventing flange erosion. Suitable for use with flat face and raised face flanges. See note at bottom of page 8 for inner ring requirements. | Style R - Basic construction type. Inner and outer diameters are reinforced with several plies of metal without filler to give greater stability and better compression and sealing characteristics. Suitable for tongue and groove or male and female or grooved to flat face flange assemblies. |

Working Shop:

Production Machinery:

| ||||

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| Cutting Machine | No Information | 3 | 5 | Acceptable |

| Laser Cutting Machine | MESSER | 1 | 2 | Acceptable |

| Shearing Machine | Q11Y-6*25 | 1 | 6 | Acceptable |

| Punching Machine | JH21-125, JD23-25 | 6 | 3 | Acceptable |

| Instrument Machine Tools | SHENHUO & C0650 | 13 | 7 | Acceptable |

| Slot Milling Machine | No Information | 6 | 4 | Acceptable |

| Bending Machine | No Information | 7 | 1 | Acceptable |

| Winding Machine | FEIXIANG & PX500B | 11 | 5 | Acceptable |

| Automatic Winding Machine | No Information | 4 | 1 | Acceptable |

| Laser Printing Machine | TIANHONG | 2 | 2 | Acceptable |

| Testing Machinery: | ||||

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| Universal Testing Machine | GRANDTRY & WA-E | 1 | 3 | Acceptable |

| Certification: | |||||

| Certified Picture | Certification Name | Certified By | Certificate No. | Product Name & Model No. | Available Date --- Expired Date |

| ISO 9001:2008 | CQM, CNAS | CN-00212Q13397R0S | Scope: Production of Metal Winding Gasket, Metal Ring Gasket, Tooth From Gasket, Coating Gasket, Non-Graphite and Graphite Enhanced Gasket | 2012/06/29 --- 2015/06/28 |

| Special Equipment Type Test Certificate | National Quality Supervision & Inspection Center of Sealing Product | TSX 71002520100040 | Flexible Graphite Spiral Wound Gasket (With Inside and Outside Ring) | 2010/03/31 --- 2049/12/31 |

| Special Equipment Type Test Certificate | Special Equipment Type Test Certificate | TSX 71002520100039 | Flexible Graphite Spiral Wound Gasket (Ordinary Type) | 2010/03/31 --- 2049/12/31 |

If you are interested in our products, please contact me in Email and I will reply to you as soon as possible.

My target of service is to satisfy your requirements.

My Email: sales02 at rilson.com.cn